1 .Blow Moulding Process

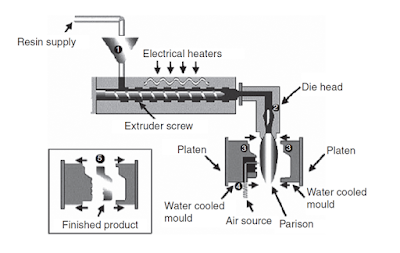

Ans:- Blow moulding is a plastic moulding process where a

thermoplastic material is heated to its forming temperature, which is below the

plasticising temperature of the plastic materials being used to form a hollow

tube called a parison Heated homogeneous plastic material is then placed

between two female mould halves.The two female mould halves are then closed and

compressed air enters via an open end of the parison via a blow pin or

needle.The air blown into the closed female mould halves forces the parison to

take the internal shape of the closed mould thereby forming the blown

component. The mould halves are cooled through suitable medium through the

entire process so that the blown parison when comes in contact solidifies

immediately. The two female moulds are then separated and shaped hollow

component is then ejected or allowed to drop out and the cycle is repeated

again.

2 .Five Stages in Blow Moulding Process

Ans:-

1. Plasticising or

melting the resin

2. Parison or preform

production

3.Inflation of the

parison or preform in a mould to produce the end part

4. Ejection of the

part

5.Trimming and finishing of the part

3 .Basic Blow Moulding Process

Ans:-

4. Parts of Extrusion Blow Mould

Ans:-

5. Applications of Extrusion Blow Moulded Parts

Ans:-

1.ANS=Packaging for

milk, fluids, medicines, cosmetics, etc.

2. Automotive fuel

tanks, oil bottles, air-ducts, and seat-backs, etc.

3. Consumer products

like toys, house-wares, sports goods, etc.

4. Drums for chemical

industries.

5. Bellow shaped

shields and double-walled carrying cases.

6. Applications of Extrusion Blow Moulded Parts

Ans:-

7. Blow Mould Design Parameters

Ans:- Design of a blow-moulded part involves:

1. The selection of

proper plastics

2. Appearance of the

product

3. End use properties

and

4. Cost economics

Blow Mould Design

Parameters

· The property requirements vary with the specific application of the product like crack

resistance, impact-resistance, chemical-resistance, etc.

·The appearance of the part covers basic design along with factors such as gloss, smoothness, wall-thickness, colour, etc.

Design of a blow moulded bottle and other shapes requires

consideration of the factors like:

· Material to be

blown

· Size and weight

of the product and mould

· Contours on the

part

· Surface texture

and engraving

· Sharp corners

and straight edges

· Blow opening

available and locations

· Parting lines

· Blow moulded

articles perform better with rounded, slanted and tapered surfaces.

· Squares and flat

surfaces with sharp corners should be avoided.

8. Blow Ratio

Ans:-

· The blow-ratio of a blow moulded part gives the amount of stretch from the parison size to

the

part size.

· For cylindrical containers,

blow-ratio = (Mould or part diameter / Parison diameter).

· This ratio is

usually between 1.5 to 3.0, it can be maximum up to 7.

9. Blow Mould Part Terminology

Ans:-

10 .Corner & Edge Rounding in Blow Mould Part

Ans:-

11 .Corner & Edge Rounding in Blow Mould Part

Ans:-

1.Rectangular

containers : at least 1/3rd depth of mould half.

2.Cylindrical

containers : at least 1/10th depth of mould half

12 .Neck finish in Blow Moulded Part

Ans:-

13 .Base Design in Blow Moulded Part

Ans:-

14. Types of Blow Moulded Container

Ans:-

15. Design Factors for Container

Ans:-

1.The type of plastic material to be used

2.The size and shape of the container

3. The neck finish size and design

4.Type of thread

5. The undercuts

6.The parting line location,

7. The surface finish

8.The fill point and weight of the container

16 .Rib Design in

Blow Mould

Ans:-

·The round containers are provided with horizontal ribs to improve hoop stiffness, and vertical ribs for compression stiffness.

·The square containers reduce stiffness, thus losing both top load strength and bulge resistance as well.

17 .Rib Design in Blow Mould

Ans:-

18 .Consideration for Bottle Design in

Blow Mould

Ans:- Important structural and Mechanical considerations in bottle design includes;

1. Vertical strength

2. Wall thickness uniformity

3. Push-up strength

4. Label considerations

5. Rigidity

6. Shape

7. Hot-fill capacity

19 Material Properties for Blow Moulding

1.ans Good thermal stability

2. Good flowability of homogenous melt

3. Sufficient stretchability of parison

4. Excellent repeatability of parison weight and length

5. Smooth parison surface

6.Compatibility with additives

7. Sufficient wide processing range

8. Excellent lot to lot consistency

20 .Blow Mouldable Polyolefin Materials

Ans:-

1 .LDPE – Low Density Polyethylene

2.LLDPE – Linear Low Density Polyethylene

3 .HDPE – High Density Polyethylene

4 .EVA – Ethylene Vinyl Acetate

5 .PP - Polypropylene

21. Blow Mouldable Polyolefin Materials

Ans:-

· Melt index describes the flow behaviour of a resin at a specified test temp (190°C), and a specified test weight (2,160 gm). Higher value indicates easy flow of the melt.

· Melt Flow Rate (MFR) describes the flow behaviour of polypropylene resins at a specified test temp (230°C) and a specified test weight (2,160 gm).

22. Blow Mould Materials

Ans:-

1. Aluminium Alloy: Aircraft grade aluminium which contains zinc, magnesium, copper and chromium is most popular choice for blow moulds. It has high thermal conductivity, good machineability, light weight and resistance to corrosion.

2.Beryllium-Copper (Be-Cu) Alloy: These alloys are used extensively due to excellent thermal conductivity, corrosion-resistance and mechanical toughness. Their drawback is high cost and poor machineability compared to aluminium.

3.Steel: It is mostly used for blow moulds for PVC or engineering resins, due to its corrosion resistance and extreme toughness. Excellent surface finish can be obtained by etching process.

4.Miscellaneous Materials: Zinc alloy (Kirksite) can be used for casting large moulds or large quantities of small moulds. It has good thermal conductivity.

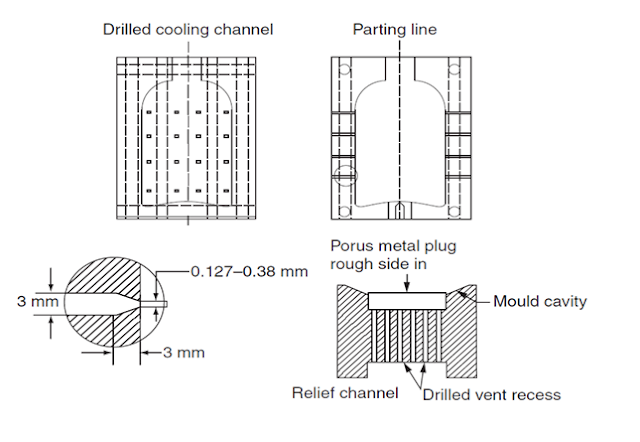

22. Blow Mould Cooling

Ans:-

23. Blow Mould

Cooling Hole Design

Ans:-

24 .Advantages & Disadvantages of Extrusion Blow Moulding

Ans:-

Advantages: It is a process for producing containers and hollow parts

preferred for moulding high volume containers.

Disadvantages: Uneven wall thickness components are produced and

difficult to achieve close dimensional tolerances; relatively low accuracy of

surface finishing is achieved.

24 Extrusion Blow Moulding Process

Ans:-

25 Stages in Extrusion Blow Moulding Process

Ans:-

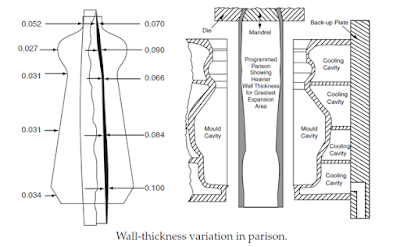

26 .Parison Programming

Ans:- Parison programming is the control of the wall-thickness, from

top to bottom, of the parison as it emerges from the die-head during extrusion

27. Pinch-off Design

Ans:-

· Pinch parting line is used in the areas where the parison is to be pinched together, creating flash.

·Pinch land length is 0.50–0.75 mm.

· Pinch angle of 45 degrees.

· Pinch relief depth is 1.5–2.0 times the wall thickness.

28 .Pinch-off Design - Types

Ans:-

29 .Venting

Ans:-

Types of Venting in blow moulds are;

a.Parting line venting

b.Cavity venting

c.Surface venting

Parting Line Venting:

· Parting line venting is used in the areas of the mould containing flat parting lines.

· It is added to only one side of the mould.

· Vent depths range from 0.05–0.08 mm with a land of 6.0 mm.

· Beyond the land, vent depth is increased to 0.25–0.40 mm through channels that lead to the atmosphere.

Cavity Venting:

· Cavity venting is added to areas inside the cavity containing deep draws and flat surfaces.

· Slotted vents are

used for non-cosmetic parts. Slot widths should be in the range of 0.40–1.25

mm.

·Pin hole vents are

used for cosmetic parts.

·A pinhole vent can

consist of one or a group of holes anywhere from 0.40–1.25 mm diameter.

Cavity

Venting – Slotted vents

·

Cavity Venting – Pin hole vents

Surface Venting

·In order to effectively vent the air from a mould, the surface of the mould should be either sandblasted or lightly textured.

·This is necessary to allow the air contained between the parison and the mould surface to migrate through the valleys of the mould surface finish and exit through the vents.

.webp)

Thanks for the messages.